The Rise of Servitisation

Rethinking business strategy to harness the power of data and insights

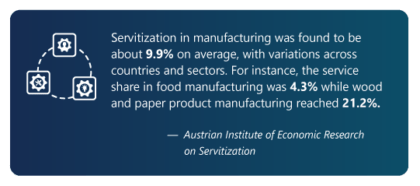

Servitisation is emerging as a significant trend in the manufacturing industry. Simply put, it marks a strategic shift from simply selling products to delivering comprehensive solutions that include products and services.

The digital revolution, with the advent of AI, IoT, and cloud computing, has played a big role in the rising popularity of servitisation. These technologies enable manufacturers to monitor their products in real-time, predict potential failures, and offer proactive maintenance services. This shift has not only opened new avenues of growth and profitability for manufacturers but has also led to improved customer satisfaction and retention — which is very important in today’s increasingly competitive market.

In this blog we will discuss the history of servitisation, how it has changed the way manufacturing companies are going to market, and its challenges.

The evolution of servitisation

First described in the 1960s, the term servitisation started to really be discussed in the 1980s. Back then, it referred to firms offering “fuller market packages or bundles” of “customer-focused goods, services, support, self-service, and knowledge.”

Since then, the concept has evolved — primarily because of technological advances. Now it is more about capturing and harnessing the power of data to offer new ways of providing value to customers beyond the sale of a product. The product itself isn’t even what is directly sold anymore and, instead, is being replaced by data-driven services (sometimes this is called Product as a Service).

Today, it is all about software. In an analysis of the 2022 Hannover Fair (the world’s largest industrial trade fair dedicated to industrial development), IoT Analytics identified four top trends, and one is that software has become front and centre for hardware companies. Whether it is traditional software or new digital services overlayed on top of traditional software, this trend dominated Hannover Messe. Even companies that make most of their revenue from hardware presented their own software or software partnerships at the event.

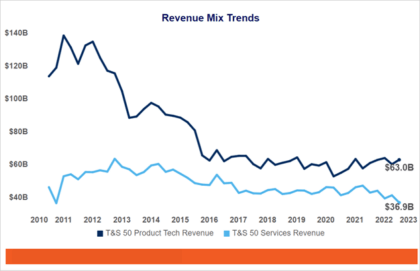

To offset the decline in CAPEX revenue and foster sustainable growth, hardware companies need to rethink their sales strategies and business models. One way is to focus more on service offers and solutions rather than solely on product sales. This would explain why field service has become such a popular revenue stream for manufacturers these days.

Digital transformation and Industry 4.0 are also contributing to servitisation. They are allowing manufacturers to design products and services with intelligence built in and customer experience as part of the sale. Manufacturers are able to successfully develop new streams of revenue by analysing how their stuff is used and gaining valuable insights from operations and maintenance data.

The cycle of delivery used to end with the point of sale. With servitisation, OEMs and other companies are able to extend the customer relationship for years through software updates and service. This has changed the way manufacturers think about sunsetting products and capitalization by extending the life of the product. Over-the-air (OTA) updates are now a regular occurrence. Cars, aircraft, computers, phones, and, yes, even industrial automation components and machinery manufacturers are already doing this.

Servitisation in the real world

There are a couple popular examples I like to point to when asked about servitisation use cases:

- Rolls-Royce, initially a British car maker but now an aerospace and defence firm, is well known. They offer “power by the hour,” letting customers use aircraft engines and receive services like maintenance without actually buying them. This allows them to track and provide significantly better maintenance, which results in more uptime for customers. In addition, by collecting this data they also learned that significantly more sand gets in the engine when flying over the Middle East. As a result, they were able to redesign their engines to better accommodate those conditions — something that may have taken years to figure out without this connected engine and service.

- Another great example is Phillips, the company a lot of people know for light bulbs. Instead of selling light bulbs, they decided to sell light through an innovative “pay per lux” model. As part of their ambition to be one of the most sustainable airports in the world, Amsterdam-Schiphol is now receiving LED lighting-as-a-service from Philips. LED lamps are incredibly efficient, however expensive to buy. Under this business model, Schiphol benefits from a 50 percent reduction in electricity consumption, without the upfront cost of buying the lamps. Philips retains ownership of the equipment and sells light as the product rather than the units.

There are many others. ABB, an industrial automation manufacturer, provides maintenance, remote monitoring, and AI-driven optimisation. And Caterpillar, a heavy equipment producer, extends equipment life through services and uses telematics for predictive maintenance.

Top challenges of servitisation

Servitisation is a big company change. Selling products to selling services — especially at a subscription or outcome-based level — often requires new IT infrastructure, new accounting, new selling, and new marketing. Basically, you have to change the way you do business. Most companies can develop a “connected product” relatively easily, but they struggle with how to turn that connected product into value through the way they promote it and then capture that value.

Manufacturers also face challenges in transitioning to servitisation due to poor data management in older, global organisations. Key insights are lost with personnel turnover and diverse cultural approaches to data complicate matters.

It also takes a lot of effort and new skill and knowledge sets to truly understand your customers’ needs and link those needs directly to an entirely different way of providing value for them.

Drive servitisation success with Hitachi Solutions

The rise of servitisation reflects the industry’s response to changing market dynamics, as manufacturers seek to differentiate themselves in an increasingly competitive landscape, boost growth and revenue streams, and increase customer retention rates. Leveraging a strategic partner with deep industry and technology expertise is a great way to get the right advice and guidance for starting your servitisation journey. That’s where Hitachi Solutions comes in.

We have the manufacturing experience, skilled professionals, and the advanced technology stack to advise, accelerate, and support your servitisation transformation. We know the process end to end — from the manufacturing floor all the way through service dispatch. And we can help you understand which components are essential for building data-driven business models that enhance your productivity and efficiency and support growth and innovation.

If you’re ready to talk servitisation, contact one of our manufacturing experts today!